Sustainable insulation of buildings is a topical issue, partly due to the climate and energy crisis. At the same time, little attention is being paid to insulating the climate systems in buildings. That’s a shame, because insulating HVAC pipes saves energy and reduces CO2 emissions. But how do you choose and use the right insulation? This blog will help you choose and apply sustainable insulation.

Your primary consideration is lifespan, when making your choice. Buildings generally have a long lifespan. Therefore, the insulation must also have a long-term contribution to energy savings and CO2 reduction. Polyethylene (PE) foam meets these durability requirements. It has excellent technical properties for thermal insulation. Moreover, it maintains that functionality throughout the life of a building. In addition, sustainable insulation has to do with environmental impact. So you want to know about the environmental performance of PE insulation material and what to look out for when considering it.

1. Environmental performance of insulation materials (LCA and EPD)

The environmental performance of insulation materials can vary over the lifetime of the product. Therefore it makes sense to assess the environmental performance at all stages of the life cycle with a Life Cycle Assessment (LCA). That way you won’t miss a thing.

EPD

Manufacturers who have carried out an LCA can have the results verified by an independent party. This party can then issue an Environmental Product Declaration (EPD). Such an EPD is a scientific foundation that is based on a standardised European methodology (in accordance with ISO 14025 and EN 15804). An EPD is not a quality mark or certificate. But it does provide transparent and neutral information about the aspects in which a product performs well or less well in terms of its environmental impact. EPDs are therefore tools for comparing the environmental performance of products. On the basis of such a comparison, you can choose products that maximise the energy performance and CO2 emissions of a building. For example, pipe insulation with low thermal conductivity will save more energy and carbon dioxide year on year throughout a building’s life cycle. read more about EPD

Saving material

To limit the environmental impact, not only the insulation value but also the amount of material is relevant. Material savings can bring additional environmental benefits such as savings in raw materials and fuel (transport). Therefore, when choosing between two insulation materials with the same thermal conductivity, the thin variant should be preferred. In this respect, PE foam is an optimal choice because it is both thin and has a high insulation value.

2. Green building rating & Cradle to Cradle

Buildings also have a life cycle, from raw material extraction to end of life. During that cycle, buildings have an impact on the environment. In order to limit this impact, green building ratings have been introduced. These green building systems or rating systems, which also function as a hallmark, make it possible to analyse and improve the sustainability of a building. The most well-known are BREEAM and LEED.

BREEAM

BREEAM (Building Research Establishment Environmental Assessment Method) was launched as the world’s first green building rating system in 1990. The British Building Research Establishment (BRE) certification method is used in more than 80 countries.

LEED

LEED (Leadership in Energy and Environmental Design) is a rating system introduced in 1998 by the US Green Building Council (USGBC). In addition to North America and Canada, LEED is also applied in Asia and Europe.

BREEAM and LEED weigh buildings or building components on their ecological, social and economic aspects and all provide useful certificates. Both also value the use of green product rating systems, such as Environmental Product Declaration (EPD) and Cradle to Cradle.

read more about green building rating

Cradle to Cradle

Cradle to Cradle (C2C) is an internationally recognised label for products that are produced safely, circularly and responsibly. C2C focuses on the use of renewable energy, maximum reuse of raw materials, materials and products and minimal value destruction. Unlike an EPD, a C2C certificate is proof that a product can be reused at the end of its lifecycle. By applying C2C certified products you contribute to environmental conservation. You can also increase the sustainability score of a building: within BREEAM and LEED you can earn points if projects have a certain minimum number or proportion of C2C certificates. All C2C certified products are included in the official international product register of the C2CPII.

Read more about cradle-to-Cradle

3. Recyclable insulation material

Circular construction includes the reuse of waste as a raw material for the production of new products. Manufacturers of insulation materials can encourage the (separate) collection of residual materials. This prevents (reusable) waste ending up with other construction waste and being destroyed.

Thermaflex promotes circularity. Therefore it has a reclaim procedure in most countries. PE foam is easy to recycle at the end of a building’s lifecycle. Through this programm installers can return their cutting and residual waste. Thermaflex then processes this waste into new insulation material.

4. Application of PE insulation material

PE foam is mechanically strong and vapour tight thanks to its closed cell structure. In addition, this insulation material is light (easy to handle) and has a long lifespan, without loss of insulation value. It is easy to cut to size (less cutting losses) and widely applicable, even in confined spaces. In order to insulate the pipes of an air-conditioning system professionally and make optimal use of the insulating properties of PE foam, the material must be applied carefully. This prevents heat loss or damage to pipes through cracks, for example.

There are different fixing methods for PE pipe insulation:

- Adhesive bonding: manually applying adhesive to the surfaces to be joined and then joining them together; this is mainly used for pipes and sheets.

- Mirror welding: bringing the ends of the insulation material into contact with a heating plate (heat plate) and making them plastic by heating them and joining them under mechanical pressure to form a whole; this is only used for pipe insulation.

- prefabricated elbows and t-pieces.

Adhesive bonding must be carried out with great precision and is therefore more laborious and time-consuming than mirror welding. Prefab pieces are in all respects (ease of assembly, health, reliability and durability) ideal for insulating corner joints. Thermaflex supports all these joining techniques and supplies all materials (including water based adhesives), accessories and tools for professional pipe insulation bonding, welding and corner joints.

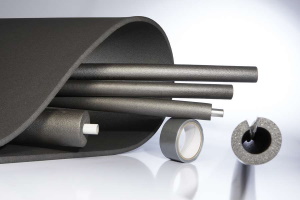

5. Our PE insulation products

ThermaSmart PRO

ThermaSmart PRO is a range of innovative insulation foam for all HVAC and sanitary applications. Available as tube, sheet, prefab elements and on coil

ThermaSmart ENEV

ThermaSmart ENEV is a similar product to ThermaSmart PRO, but has lower lambda value as it is designed to meet German energy saving legislation. Available as tube, prefab elements and on coil.

ThermaEco

ZZ

ThermaEco ZZ is a halogen-free insulation, for applications that do not require compliance with the highest fire resistance standards. Available as tube and prefab elements

ThermaEco

FRZ HF

ThermaEco FRZ HF is a halogen-free insulation, for applications that do not require compliance with the highest fire resistance standards. Available as tube and prefab elements

ThermaSmart (PRO and ENEV) and ThermaEco (FRZ and ZZ) pipe and sheet insulation is used to insulate copper, iron and plastic piping and ducting in commercial, residential and institutional buildings, and in industrial applications. The thermal insulation is suitable for heating, cooling, refrigeration and aircondioning systems, operating at temperatures from -80°C up to 95°C.

Setting sustainability standards

Thermaflex has completed several C2C processes resulting in the certification of several products, including PE tube insulation. In 2021, Thermaflex received C2C Bronze certification from EPEA for ThermaSmart PRO (tubes and sheets). C2C products are listed in several independent databases, such as:

Thermaflex provides transparency in all aspects of sustainability; whether it concerns production, material choice or product features. That is why we adopted EPD as an international standard that independently verifies and registers a transparent and comparable life-cycle story about the environmental impact of our components.

Markus Thürnbeck-KissGroup Product Manager

Ton van Soest

Technical insulation Expert